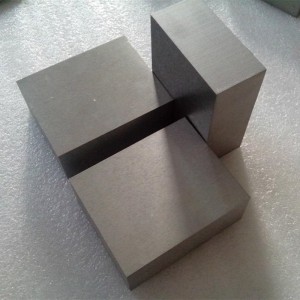

Silver Tungsten Alloy

Silver tungsten gami babban haɗe ne na ban mamaki na ƙarfe biyu na ban mamaki, azurfa da tungsten, waɗanda ke ba da saiti na musamman da aikace-aikace.

Alloy ya haɗu da kyakkyawan ingancin wutar lantarki na azurfa tare da babban wurin narkewa, tauri, da juriya na tungsten. Wannan ya sa ya dace sosai don aikace-aikacen buƙatu daban-daban a cikin filayen lantarki da na inji.

A cikin masana'antar lantarki, ana amfani da gami na tungsten na azurfa a cikin lambobin lantarki da masu sauyawa. Ƙarfinsa don jure yanayin zafi mai zafi da arcing yana sa ya zama abin dogaro a cikin waɗannan mahimman abubuwan. Alal misali, a cikin tsarin lantarki mai ƙarfi, inda halin yanzu yana da mahimmanci kuma hadarin zafi yana da yawa, yin amfani da tungsten na azurfa yana tabbatar da ingantaccen aiki da aminci.

A cikin injiniyoyi, yana samun aikace-aikace a cikin kayan aiki kuma ya mutu saboda taurinsa da dorewa. Abubuwan da aka yi daga wannan gami na iya jure matsanancin damuwa na inji da lalacewa, suna tsawaita rayuwarsu da haɓaka aiki.

Samar da kayan aikin tungsten na azurfa sau da yawa ya haɗa da matakai masu rikitarwa don cimma abubuwan da ake so da microstructure. Wannan yana tabbatar da mafi kyawun ma'auni na kaddarorin don takamaiman aikace-aikace.

Binciken da ci gaba a fagen tungsten gami na azurfa yana ci gaba da haɓakawa, buɗe sabbin hanyoyi da haɓakawa. Masana kimiyya da injiniyoyi koyaushe suna binciken hanyoyin haɓaka kaddarorin sa da faɗaɗa kewayon aikace-aikacen sa.

A ƙarshe, azurfa tungsten alloy ya tsaya a matsayin shaida ga basirar ɗan adam a kimiyyar kayan aiki, yana ba da mafita ga wasu matsalolin injiniya da fasaha mafi ƙalubale. Haɗin kai na musamman ya sa ya zama abu mai mahimmanci a cikin masana'antu daban-daban, yana tsara duniyar zamani tare da kasancewarsa da damarsa.

Ƙirƙirar azurfa tungsten gami:

Foda Metallurgy:

Wannan hanya ce gama gari. Ana haɗe foda masu kyau na azurfa da tungsten a cikin adadin da ake so. Sannan ana hada cakuda a karkashin babban matsi don samar da karamin karamin koren. Wannan ɗan ƙaramin ƙaramin abu daga baya yana jujjuya shi a babban zafin jiki don haɗa ɓangarorin tare da samar da ingantaccen gami. Misali, a wasu lokuta, ana iya fara niƙa foda tare don tabbatar da cakuda mai kama da juna.

Zuba Ruwan Kemikal (CVD):

A cikin wannan hanyar, ana shigar da maƙallan gas ɗin da ke ɗauke da azurfa da tungsten a cikin ɗakin amsawa. Ƙarƙashin ƙayyadaddun yanayi na zafin jiki da matsa lamba, masu ƙididdigewa suna amsawa da ajiyewa a kan wani abu don samar da alloy Layer. Wannan dabarar tana ba da damar sarrafa daidaitaccen abun da ke cikin gami da microstructure.

Electroplating:

Hakanan ana iya ƙirƙira gami da tungsten na azurfa ta hanyar lantarki. Tungsten substrate yana nutsewa a cikin electrolyte mai ɗauke da ions na azurfa. Ta hanyar amfani da na'urar lantarki, ana ajiye azurfa a saman tungsten, wanda ke samar da alloy Layer. Ana iya daidaita wannan tsari don cimma nau'ikan kauri daban-daban da abubuwan haɗin gwiwa na murfin gami.

Sinter-HIP (Hot Isostatic Pressing):

An fara yin cakuda foda sannan a sanya shi a matsawa isostatic mai zafi. Wannan yana taimakawa wajen kawar da porosity da inganta yawa da kayan aikin injiniya na kayan da aka ƙera.

Zaɓin hanyar ƙirƙira ya dogara da dalilai daban-daban kamar abubuwan da ake so na alloy na ƙarshe, siffar da girman ɓangaren da za a samar, da sikelin samarwa. Kowace hanya tana da fa'idodi da gazawarta, kuma galibi ana iya amfani da haɗin waɗannan fasahohin don cimma sakamako mafi kyau.

Silver tungsten alloy yana da takamaiman aikace-aikace da yawa saboda musamman kaddarorinsa:

Lambobin Lantarki:

● A cikin manyan na'urori masu ɗaukar wuta, inda zai iya ɗaukar manyan igiyoyin ruwa da sauyawa akai-akai ba tare da lalacewa ko lalacewa ba.

● A cikin relays da masu tuntuɓar masana'antu don tsarin kula da masana'antu, samar da ingantaccen haɗin lantarki da kuma tsawon rayuwar sabis.

Electrodes:

● Don kayan aikin fitarwa na lantarki (EDM), inda babban ƙarfinsa da juriya don sawa yana tabbatar da daidaitaccen cire kayan aiki.

● A cikin na'urorin walda na arc, suna ba da kyakkyawan yanayin zafi da karko.

Abubuwan Jirgin Sama:

● A cikin sassan injunan jirgin sama da tsarin jiragen sama waɗanda ke buƙatar kayan aiki tare da ƙarfin zafin jiki da ƙarfin injin.

Gudanar da thermal:

● Yayin da zafi ke nutsewa a cikin na'urorin lantarki, yadda ya dace da gudanarwa da watsar da zafi.

Kayan aiki da Mutuwa:

● Don yin tambari da ƙirƙirar ayyuka, musamman a aikace-aikacen da taurin kai da juriya suke da mahimmanci.

Kayan ado:

● Saboda kyan gani da dorewa, ana iya amfani dashi wajen ƙirƙirar kayan ado na musamman.

Misali, a cikin masana'antar kera motoci, ana amfani da lambobin tungsten gami na azurfa a cikin injin farawa don tabbatar da abin dogaro na injin a ƙarƙashin yanayi daban-daban. A fagen sadarwa, ana amfani da shi a cikin manyan maɓalli don kiyaye amincin sigina da rage asarar sigina.

Silver Tungsten Alloy Properties

| Lambar lamba. | Haɗin Sinadari% | Kayan aikin injiniya | ||||||

| Ag | Rashin tsarki≤ | W | Yawan yawa (g/cm3 ) ≥ | Tauri HB ≥ | RES (μΩ·cm) ≤ | Gudanarwa IACS / % ≥ | TRS/Mpa ≥ | |

| AgW (30) | 70± 1.5 | 0.5 | Ma'auni | 11.75 | 75 | 2.3 | 75 | |

| AgW (40) | 60± 1.5 | 0.5 | Ma'auni | 12.40 | 85 | 2.6 | 66 | |

| AgW (50) | 50± 1.5 | 0.5 | Ma'auni | 13.15 | 105 | 3.0 | 57 | |

| AgW (55) | 45± 2.0 | 0.5 | Ma'auni | 13.55 | 115 | 3.2 | 54 | |

| AgW (60) | 40± 2.0 | 0.5 | Ma'auni | 14.00 | 125 | 3.4 | 51 | |

| AgW (65) | 35± 2.0 | 0.5 | Ma'auni | 14.50 | 135 | 3.6 | 48 | |

| AgW (70) | 30± 2.0 | 0.5 | Ma'auni | 14.90 | 150 | 3.8 | 45 | 657 |

| AgW (75) | 25± 2.0 | 0.5 | Ma'auni | 15.40 | 165 | 4.2 | 41 | 686 |

| AgW (80) | 20± 2.0 | 0.5 | Ma'auni | 16.10 | 180 | 4.6 | 37 | 726 |