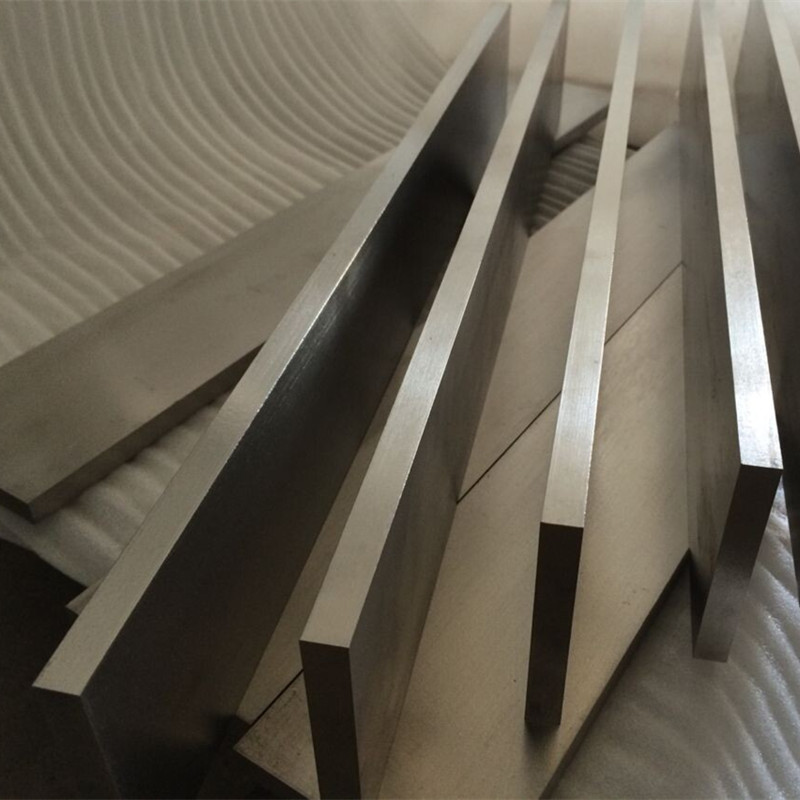

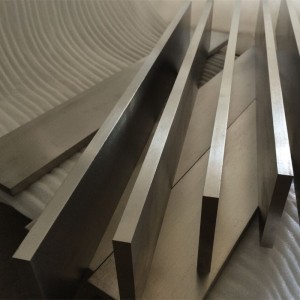

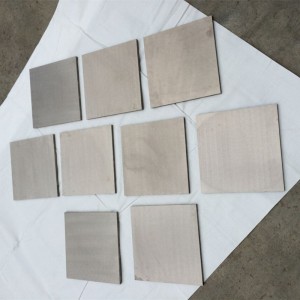

Tsaftace Tabbataccen Titanium Plate Titanium Alloy Sheet

Bayani

Tabbataccen Tabbataccen Tabbataccen Titanium / Titanium Alloy Sheet Takaddun Shaida:

Material Grade: Gr1, Gr2, Gr3, Gr4, Gr5, Gr7, Gr6, Gr9, Gr11, Gr12, Gr16, Gr17, Gr25, TA0,TA1,TA2,TA5,TA6,TA7,TA9,TA10,TB2,TC1,TC2 , TC3, TC4

Standard ASTM B265, ASME SB265, DIN17851, TiA16Zr5Mo1.5, JIS4100-2007, GB3461-2007

Girman:

Cold birgima: Kauri 0.02mm ~ 5mm * Fadi 1500mm max * Dogon 2500mm max

Hot birgima: Kauri 5mm ~ 100mm * Wide 3000mm max * Dogon 6000mm max

Titanium Alloy Plate Application

1. Dangane da High tsanani, titanium kayayyakin ƙarfi tensile ƙarfi iya zama har zuwa 180Kg/mm².

2. Titanium da titanium gami a cikin masana'antar jirgin sama, ana kiranta "karfe na sararin samaniya"; Bugu da kari, a cikin shipbuilding masana'antu, sunadarai masana'antu, masana'antu sassa, sadarwa kayan aiki, da wuya gami, da dai sauransu sun ƙara m aikace-aikace.

3. Bugu da ƙari, saboda titanium alloy tare da jikin mutum yana da dacewa mai kyau sosai, don haka daɗaɗɗen titanium na iya zama ƙashi na wucin gadi.

6AL-4V titanium Gr5 kuma aka sani da Ti6Al4V, Ti-6Al-4V, Ti6-4 ko Titanium 6Al-4V Alloy, shine abin da aka fi amfani dashi. Yana da ƙarfi sosai fiye da tsantsar titanium na kasuwanci yayin da yake da tauri iri ɗaya da kaddarorin thermal. AMS 4911 6AL-4V titanium sheet & farantin babban zaɓi ne na takarda titanium na jirgin sama a cikin takamaiman bayani dalla-dalla.

Siffar AMS 4911 6AL-4V Titanium Sheet & Plate

● Ƙarfin Ƙarfin Ƙarfin Ƙarfin Ƙarfin Ƙarfi.

● Kyakkyawan juriya ga tasirin zafi.

● Ƙananan Modulus na Ƙarfafawa.

● Kyawawan kaddarorin thermal.

Sinadarin Haɗin Titanium da Alloy na Titanium

| Daraja | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | Bal |

Ƙarfin Ƙarfin Ƙarfin Titanium da Titanium Alloy

| Daraja | Tsawaita(%) | Ƙarfin Tensile (min) | Ƙarfin Haɓaka (min) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |