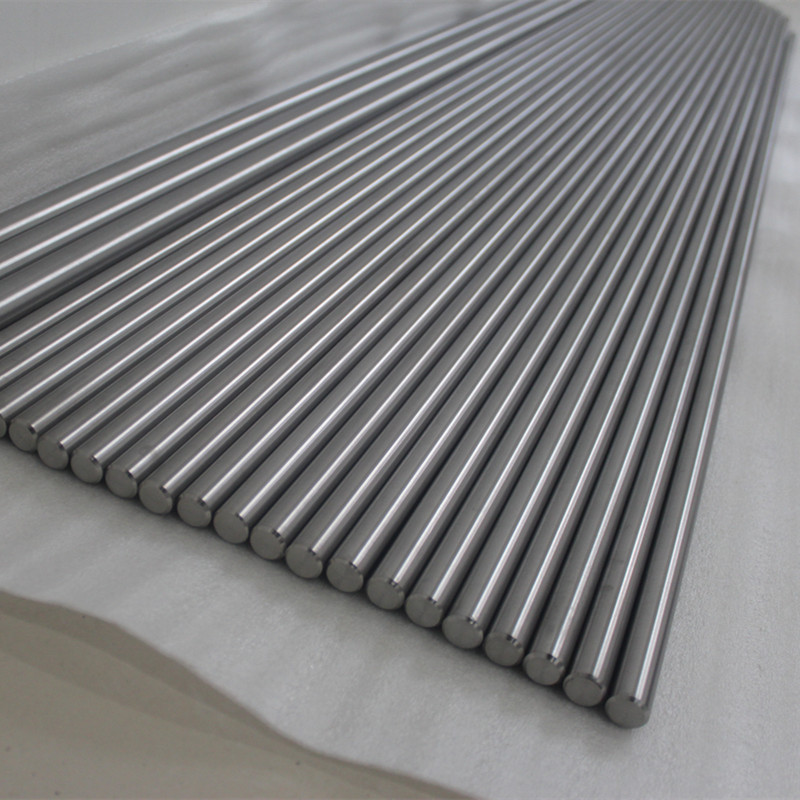

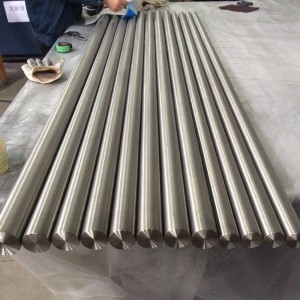

Tsabtace Titanium Rod Titanium Alloy Bar

Bayani

sandar titanium shine ɗanyen kayan da ake amfani dashi don yin gami da ƙarfe na titanium. Yana da halaye na ƙananan ƙima, ƙarfin ƙarfi da kyakkyawan juriya na lalata. A cikin masana'antar sararin samaniya, ana amfani da sandar titanium sosai wajen kera sassan tsarin jirgin sama da nozzles na roka; a cikin masana'antar sinadarai, ana amfani da shi azaman mai ɗaukar hoto da na'urar tsarkakewa don electrolytes; a cikin masana'antar injuna, ana iya amfani da shi azaman mai musayar zafi da kayan daɗaɗɗa.

A cikin masana'antar ƙarfe, ana amfani da sandar titanium / mashaya don samar da ƙarfe mai tsafta iri-iri, bakin karfe, ƙarfe mai jure zafi da ƙarfe na musamman. Bugu da ƙari, ana amfani da ita wajen kera duwatsu masu daraja ta wucin gadi da lu'ulu'u na rutile zircon na wucin gadi, zanen yumbu na piezoelectric don masana'antar lantarki, da madaidaicin simintin gyaran fuska daban-daban.

Tsabtace Tsabtace Tsabtace Tsabtace Tsabtace Sanda / Titanium Alloy Bar Specificities

Titanium Alloy Grade:Gr.5, Gr.23, Ti-6Al-4v-Eli, TI5, BT6, Ti-6al-7Nb.

Matsayin Titanium Tsantsar Kasuwanci:Gr.3, Gr.4 kasuwanci mai tsafta.

Tsawon Diamita:Ø5mm, Ø6mm, Ø8mm, Ø12mm, Ø14mm, Ø25mm, Ø30mm, da dai sauransu.

Matsayin Haƙuri:ISO 286.

Daidaito:ASTM F67, ASTM F136, ISO 5832.

Tsawon samuwa:2.5 m ~ 3 m (98.4 ~ 118.1"), ko musamman.

Daidaito:cikakke ga CNC machining.

Ana iya ba da duk sanduna / sanduna na Titanium da diamita na musamman ko tsayi, don dacewa da buƙatun Abokin ciniki.

Fasalin sandunan alloy na titanium:Kyakkyawan elasticity, babban ƙarfi da microstructure kama.

Akwai Daraja Titanium

| ASTM B265 | GB/T 3620.1 | JIS H4600 | Abun ciki (wt%) | ||||||

| N, Max | C, Max | H, Max | Fe, Max | O, Max | Wasu | ||||

| TsaftaceTitanium | Gr.1 | TA1 | Darasi na 1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | - |

| Gr.2 | TA2 | Darasi na 2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | - | |

| Gr.3 | TA3 | Darasi na 3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | - | |

| Gr.4 | TA 4 | Darasi na 4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | - | |

| TitaniumAlloy | Gr.5 | TC4Ti-6Al-4V | Darasi na 60 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | Al:5.5-6.75;V: 3.5-4.5 |

| Gr.7 | TA9 | Darasi na 12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | Littafin: 0.12-0.25 | |

| Gr.11 | TA9-1 | Darasi na 11 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Littafin: 0.12-0.25 | |

| Gr.23 | TC4 ELI | Babban darajar 60E | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 | Al:5.5-6.5;V: 3.5-4.5 | |