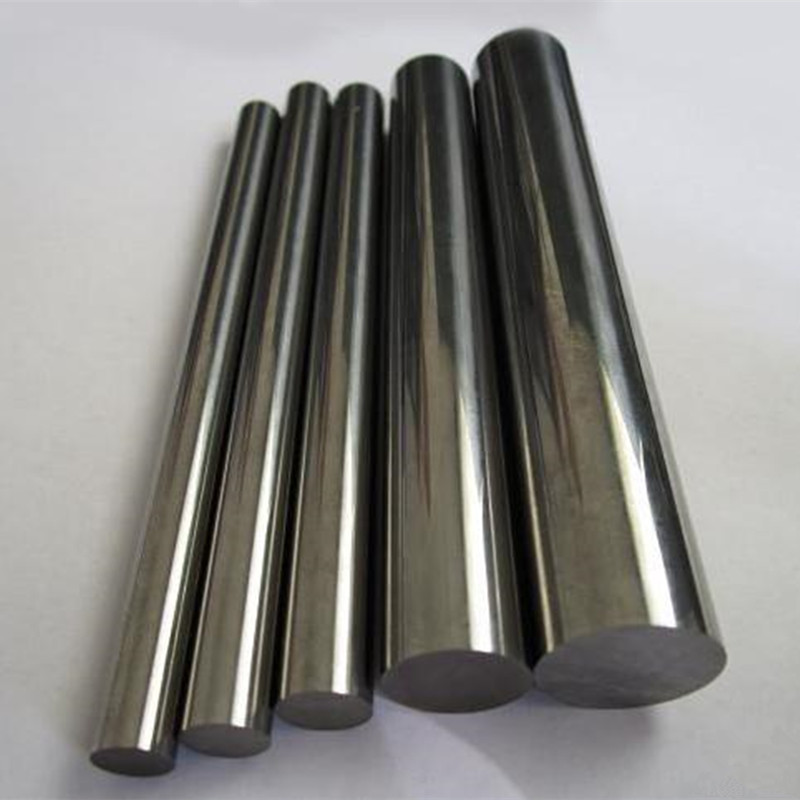

Tungsten Heavy Alloy Rod

Ƙayyadaddun bayanai

Tungsten Heavy Alloy Grade:

W90NiFe/W92.5NiFe/W93NiFe/W95NiFe/W97NiFe (Dan kadan Magnetic).

W90NiCu/W92.5NiCu/W93NiCu/W95NiCu/W97NiCu (Maɗaukaki).

Yawan yawa:16.8-18.8g/cm3.

saman:Machined & Ground.

Daidaito:Saukewa: ASTM B777.

Diamita:5.0mm - 80mm.

Tsawon:50mm-350mm.

Tungsten High Density Alloy Abvantages

Babban yawa (har zuwa 65% mai yawa fiye da Lead).

Abubuwan da ke da yawa suna wanzu (Tungsten tsantsa, Zinariya, ƙarfe na rukuni na platinum) amma amfanin su yana iyakance ta samuwa, iya aiki da farashi.

Samar da taro inda sararin girma ya iyakance.

Mahimmancin nauyi mai mahimmanci inda ake buƙatar daidaito a cikin jeri na taro.

Sanya nauyi a cikin yanayi inda iska ke da tasiri mai mahimmanci.

Abubuwan thermal na Tungsten Heavy Alloys

Babban zafin jiki mai laushi.

Ƙananan ƙarancin zafin jiki da ƙananan haɓakar haɓakawa yana ba da kayan aiki mai girma ga gajiyar thermal.

Excellent soldering yashwa juriya ga narkakkar aluminum.Ƙarfafa a yanayin zafi mai girma tare da kwanciyar hankali na thermal.

Tungsten High Density Alloy Mechanical Properties

● Maɗaukakin Matasa na elasticity.Ba ya rarrafe yayin fuskantar manyan ƙarfi, sabanin Guba.

● Duk da ƙarfinsu, sun kasance masu juriya ga fashewa.

Matsakaicin taurin gami shine yawanci 20-35 Hardness HRC.

Tungsten Based Alloy

| Nau'in Aloy(%) | HD17 90W 6Ni 4Cu | HD17D 90W 7Ni 3Fe | HD17.5 92.5W 5.25Ni 2.25Fe | HD17.6 92.5W Balance Ni, Fe, Mo | HD17.7 93W Balance Ni, Fe, Mo | HD18 95W 3.5Ni 1.5Cu | HD18D 95W 3.5Ni 1.5Fe | HD18.5 97W 2.1Ni .9Fe |

| MIL-T-21014 | Darasi na 1 | Darasi na 1 | Darasi na 1 | - | - | Darasi na 3 | Darasi na 3 | Darasi na 4 |

| SAE-AMS-T-21014 | Darasi na 1 | Darasi na 1 | Darasi na 2 | - | - | Darasi na 3 | Darasi na 3 | Darasi na 4 |

| Saukewa: AMS7725C | 7725 C | 7725 C | -- | -- | -- | -- | -- | -- |

| Saukewa: ASTM B777-87 | Darasi na 1 | Darasi na 1 | Darasi na 2 | - | - | Darasi na 3 | Darasi na 3 | Darasi na 4 |

| Yawan yawa(g/cc) | 17.1 | 17.1 | 17.5 | 17.6 | 17.7 | 18 | 18 | 18.5 |

| Yawan yawa(lbs/in3) | 0.614 | 0.614 | 0.632 | 0.636 | 0.639 | 0.65 | 0.65 | 0.668 |

| Halin Hardness RC | 24 | 25 | 26 | 30 | 32 | 27 | 27 | 28 |

| Ƙarfin Ƙarfin Ƙarfafa Min(ksi) | 110,000 | 120,000 | 114,000 | 120,000 | 125,000 | 110,000 | 120,000 | 123,000 |

| 0.2% Rage Ƙarfin Haɓakawa Min(ksi) | 80,000 | 88,000 | 84,000 | 90,000 | 95,000 | 85,000 | 90,000 | 85,000 |

| Mafi ƙarancin % Tsawaitawa(1" tsayin tsayi) | 6 | 10 | 7 | 4 | 4 | 7 | 7 | 5 |

| Matsakaicin Ƙimar Ƙarfafawa(PSI) | 45,000 | 52,000 | 46,000 | 55,000 | 60,000 | 45,000 | 44,000 | 45,000 |

| Modulus na Elasticity(x106psi) | 40 x106 | 45 x106 | 47 x106 | 52 x106 | 53 x106 | 45 x106 | 50 x106 | 53 x106 |

| Ƙididdigar Ƙarfafa Ƙarfafawar Thermal x10-6/0C(20-400C) | 5.4 | 4.61 | 4.62 | 4.5 | 4.5 | 4.43 | 4.6 | 4.5 |

| Thermal Conductivity(Raka'a CGS) | 0.23 | 0.18 | 0.2 | 0.27 | 0.27 | 0.33 | 0.26 | 0.3 |

| Wutar Lantarki(% IACS) | 14 | 10 | 13 | 14 | 14 | 16 | 13 | 17 |

| Magnetic | No | Dan kadan | Dan kadan | Dan kadan | Dan kadan | No | Dan kadan | Dan kadan |